Cast Tungsten Carbide

KoneCarbide offers top-quality cast tungsten carbide that is widely used in the mining, construction, oil, and gas industries.

Applications: Hardfacing coatings; Diamond drill bit matrix

Chemical Composition: W (95%-96%), T.C (3.8%-4.1%), F.C (≤0.08%), Cr (≤0.1%), V (≤0.05%), Si (≤0.02%), O (≤0.05%), Fe (≤0.3%).

Hardness: 2000 HV

Melting point: 2525℃

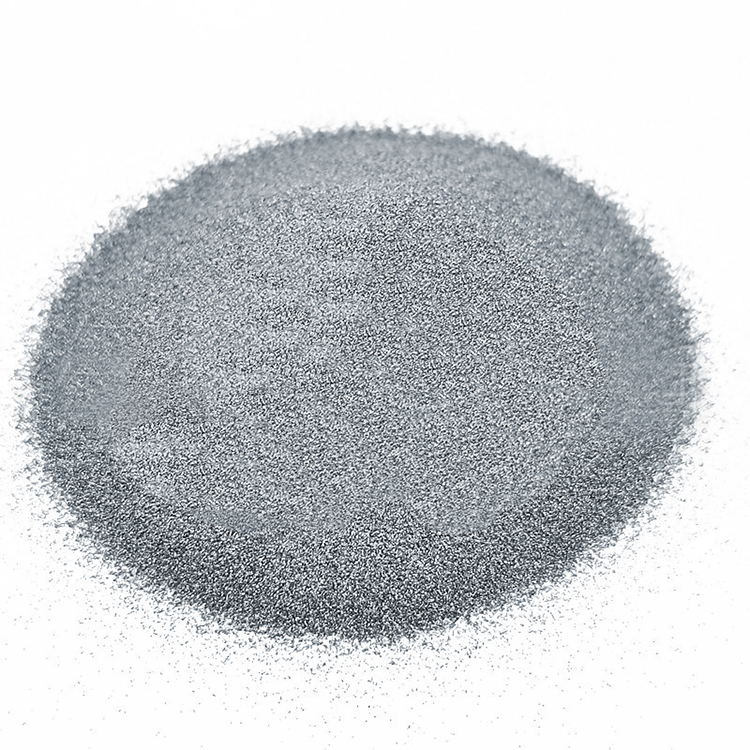

Appearance: Gray particle/powder

For further information (MOQ, delivery, and more), please request a quote today! Our salespeople are ready to provide the best solution for you.

Cast Tungsten Carbide description:

Cast tungsten carbide is made from tungsten powder and tungsten carbide powder. The powder mixture is then compacted in the graphite boat. Next, the compacted mixture is melted at approximately 2900℃ in a smelting furnace for a certain time, generating the phase composition: W2C and WC.

Cast tungsten carbide can be used as wear parts or hardfacing coatings for tools like oilfield cutting tools. Besides, it is frequently used as the diamond drill bit matrix material to enhance the performance and longevity of the bit.

KoneCarbide manufactures and supplies outperformed cast tungsten carbide, featuring excellent wear resistance, extremely high hardness (2000 HV) and melting point (2525℃), and weldability. From powder selection to final inspection, we have established a set of standards for each step, ensuring the premium and consistent quality of our cast tungsten carbide.

| Particle Size |

|---|

| -840+590μm (20-30mesh) |

| -590+420μm (30-40mesh) |

| -420+250μm (40-60mesh) |

| -250+177μm (60-80mesh) |

| -177+125μm (80-120mesh) |

| -250+44μm (60-325mesh) |

| -210+38μm (70-400mesh) |

| -177+74μm (80-200mesh) |

| -149+105μm (100-140mesh) |

| -149+63μm (100-230mesh) |

| -125+88μm (120-170mesh) |

| -105+74μm (140-200mesh) |

| -88+44μm (170-325mesh) |

| -74+44μm (200-325mesh) |

| -44μm (-325mesh) |

| -38μm (-400mesh) |