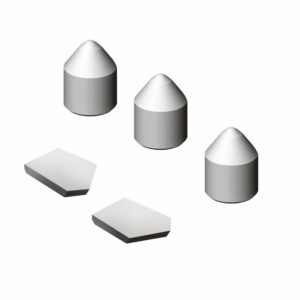

Carbide Buttons

Carbide, or tungsten carbide, is one of the hardest alloys that have a wide range of applications, such as mining, construction, oil and gas, machine tools, cutting tools, wear parts, etc. Compared to steel, tungsten carbide is much harder and has a longer service life. When you need a metal that is harder than steel and more resistant to wear and impact, tungsten carbide can definitely meet your requirements. Although diamond is even harder than carbide, it is not an affordable alternative.

Buttons or inserts made from tungsten carbide play a crucial role in the mining and construction industries. For those drilling rigs, carbide buttons can reduce downtime and improve productivity.

As an ISO-certified supplier, KoneCarbide has been dedicated to tungsten carbide button manufacturing for 10 years. We use 100% virgin materials and micro-grain tungsten carbide to guarantee tungsten carbide buttons’ quality at the source. The HIP sintering process can enhance mechanical properties and workability. Our advanced in-house facilities for quality inspection ensure all the carbide buttons’ quality before shipment.

Carbide buttons with varied sizes and grades are available and we also offer customization services. For further information (MOQ, price, delivery, etc), please request for quotation. Our sales team and engineers are ready to provide the most cost-efficient solutions for you.

Products

- Carbide Buttons

Carbide Buttons For Coal Mining Bits

- Carbide Buttons

Carbide Buttons For Road Milling Teeth

- Carbide Buttons

Carbide Buttons For Bullet Teeth

- Carbide Buttons

Carbide Buttons For Roadheader Bits

- Carbide Buttons

Carbide Buttons For DTH Bits

- Carbide Buttons

Carbide Buttons For Cross & Tapered Chisel Bits

- Carbide Buttons

Carbide Buttons For Geological Exploration Drilling

- Carbide Blanks

Carbide Buttons For Tricone Drill Bits