Decanter Centrifuge Wear Parts

KoneCarbide manufactures and supplies tungsten carbide wear parts for decanter centrifuges.

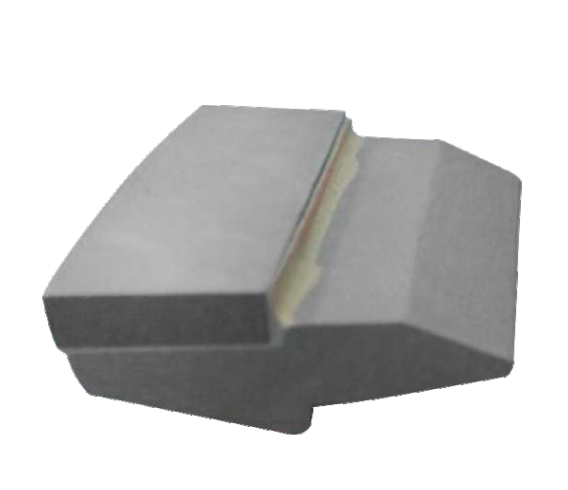

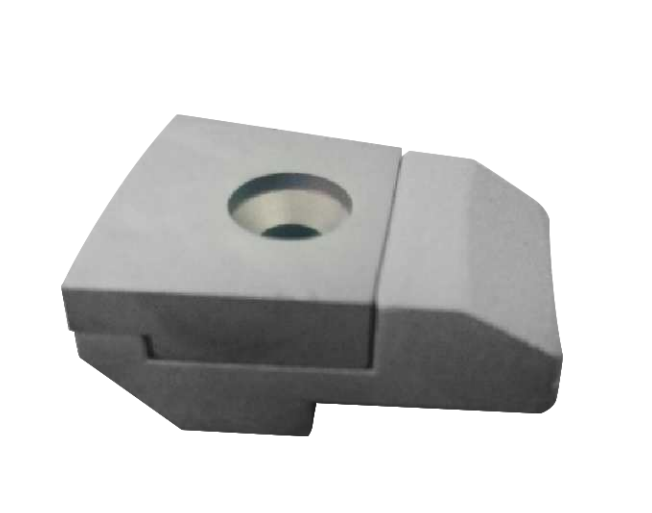

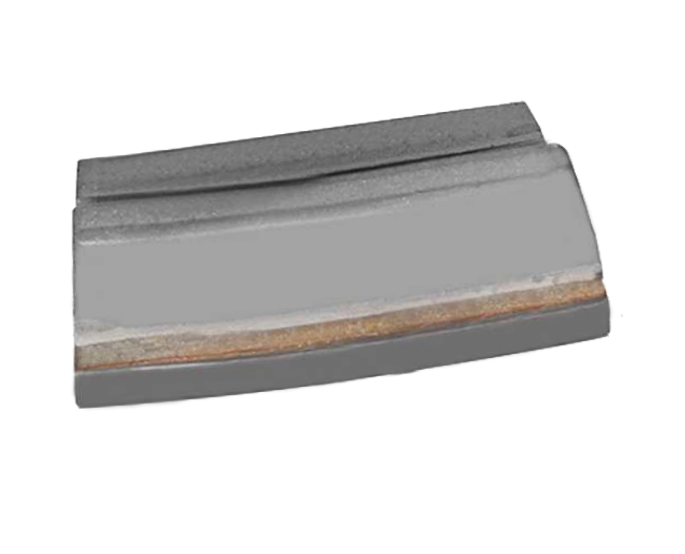

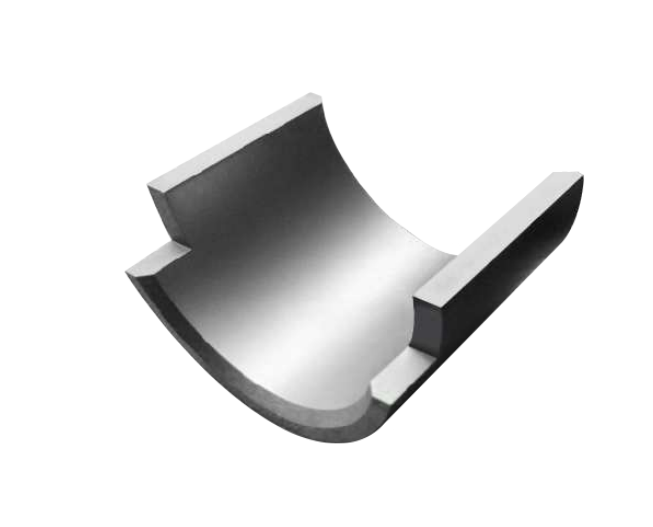

Wear Parts: Tungsten carbide tiles, discharge nozzles, wear liners, and more.

Request a quote for further information (MOQ, price, delivery) or other decanter centrifuge wear parts.

Decanter Centrifuge Wear Parts Description:

Decanter centrifuges require high wear and corrosion resistance due to abrasive particles in the media and extreme pressure produced by equipment operation. Decanter centrifuge systems usually operate at a high RPM to separate high-density from low-density particles, thus creating high wear, impact, and corrosion.

As an ISO 9001:2015 certified tungsten carbide manufacturer, KoneCarbide has been dedicated to supplying premium and consistent quality tungsten carbide wear parts for centrifugal separation equipment in different industries, including oil and gas, wastewater treatment, chemical, and food processing. We always tackle wear, heat, and corrosion problems to improve productivity and extend tool service life for our customers.

We manufacture several carbide wear components including tungsten carbide tiles, discharge nozzles, and wear liners.

KoneCarbide Decanter Centrifuge Wear Parts Features:

- 100% virgin materials

- Excellent wear and corrosion resistance

- Extended service life

- Enhanced performance and productivity

- Varied grades and sizes

- Both standard and customized wear components are available

For further information (MOQ, price, delivery, etc), or if you are looking for other centrifuge carbide wear parts apart from the above ones, please contact us or directly request a quote. Our sales team and engineers are ready to provide the most cost-efficient solutions for you.