Carbide Hardfacing

Hardfacing is a weld treatment technique in the oil and gas industry to extend the service life of equipment components by welding high wear-resistant materials onto the surface of components. There are many types of wear-resistant materials, but tungsten carbide is the most widely used one for hardfacing due to its excellent wear, corrosion, and abrasion resistance. Once welded on the surface of the substrate, the components become much more wear-resistant. Although tungsten carbide is an expensive material for hardfacing, it will greatly extend the service life of key wear parts and increase efficiency and productivity.

KoneCarbide manufactures premium and consistent quality tungsten carbide hardfacing materials, including tungsten carbide composite rods (welding rods), tungsten carbide pellets, crushed tungsten carbide grits, cast tungsten carbide, and gauge protection inserts. Besides, we also supply Titanium Carbide hardfacing grits and Power for PTA/Laser Cladding. Request for quotation for detailed information (MOQ, price, delivery, etc) if you are interested in our tungsten carbide hardfacing products. Our sales team and engineers are ready to provide the most cost-efficient solution for you.

Features:

- High-grade carbide;

- Top and consistent quality;

- Excellent wear, corrosion, and abrasion resistance;

- Greatly prolong the service life of equipment;

- Competitive price;

- Customization service.

Products

- Carbide Hardfacing

Tungsten Carbide Composite Rods

- Carbide Hardfacing

Crushed Tungsten Carbide Grits

- Carbide Hardfacing

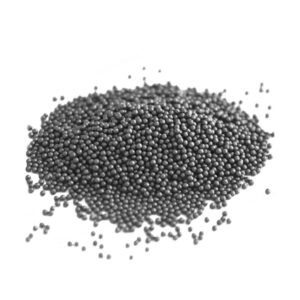

Tungsten Carbide Pellets

- Carbide Hardfacing

Cast Tungsten Carbide

- Carbide Hardfacing

Powder for PTA/Laser Cladding

- Carbide Hardfacing

Titanium Carbide (TiC) Hardfacing Grits

- Carbide Hardfacing

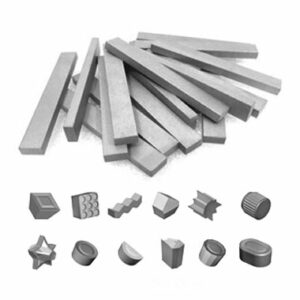

Gauge Protection