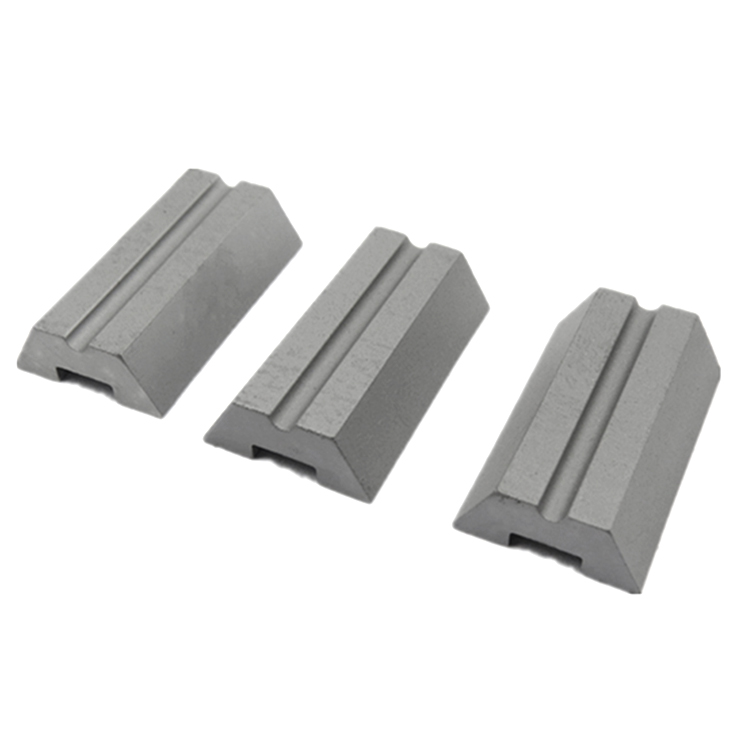

Carbide Dies

KoneCarbide supplies top-quality carbide dies for steel parts fabrication.

What we offer:

- Carbide Shaving Dies

- Carbide Cold Heading Dies

- Carbide Drawing Dies

- Carbide Die Sets

- Custom Carbide Dies

Grade: GM30, GM35

Unground carbide dies are available.

For further information (MOQ, price, delivery) or if you need customization services, please request a quote.

Carbide Dies Description:

Carbide dies are commonly used for steel forming in a wide range of industries, such as aerospace, machine manufacturing, and electronics, just to name a few. Compared to steel, carbide dies are superior because of their higher strength and longer service life. Tungsten carbide dies dramatically increase productivity by reducing the number of wear part replacements and equipment downtime.

There are several types of carbide dies, including cold heading dies, shaving dies, drawing dies, extrusion dies, and more. Carbide shaving dies are used to remove defects such as oxide layer, sonim, scaling, and other coatings from the surface of steel parts, including bars, pipes, tubes, etc, leaving a smoother surface. Cold heading dies, also called cold forming dies, are used in cold heading and cold forming works. They are typically used with a cold header machine. Carbide cold heading dies are most frequently applied in the manufacturing of fasteners such as bolts, screws, nuts, rivets, and nails.

Konecarbide manufactures and supplies carbide shaving dies, carbide cold heading dies, carbide drawing dies, and carbide die sets. Apart from these standard dies, we also provide non-standard and customized dies.

KoneCarbide Carbide Die Features:

- 100% virgin WC powder

- High strength, high wear resistance, high efficiency

- Reduced downtime and high productivity

- Cost-effective production

- Competitive prices

- Customization services

Customization Services:

Non-standard and customized carbide dies are both available, and varied sizes and grades can be found in KoneCarbide.

| Grade | Grain Size | Density (g/cm³) | Hardness (HRa) | T.R.S (N/mm²) |

|---|---|---|---|---|

| GM30 | Medium | 14 | 87.5 | 2650 |

| GM35 | Medium | 13.2 | 85 | 2800 |