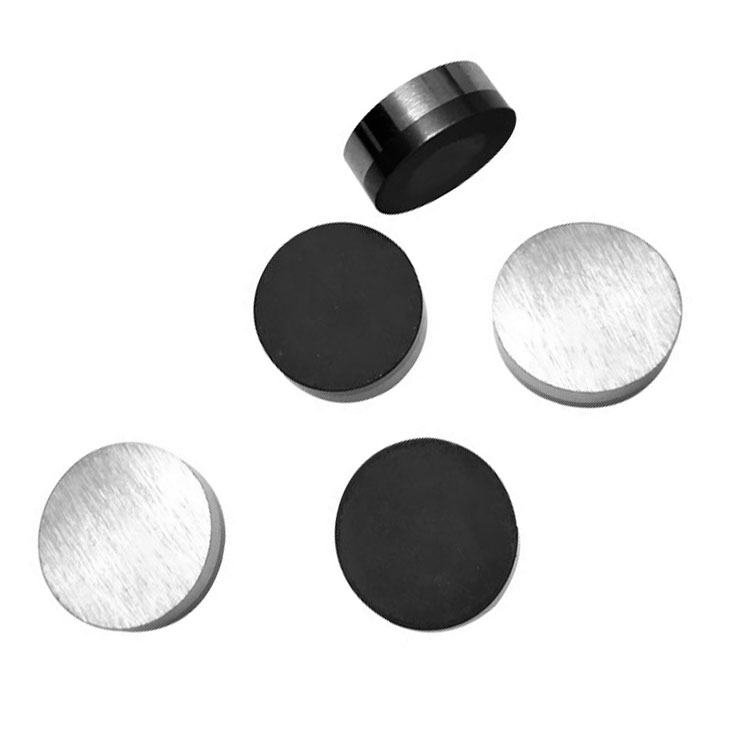

PDC Cutters

KoneCarbide manufactures and supplies top and consistent quality PDC inserts/cutters for the oil and gas industry.

Applications: Soft to medium-hard rock formation

Request a quote for further information (MOQ, price, delivery).

PDC Cutter Description:

For downhole tools, the drilling inserts or buttons are extremely important, which directly influence the efficiency and productivity of the projects. PDC cutters/inserts, or polycrystalline diamond (PCD) compact inserts, are undoubtedly the most widely used drilling buttons in the oil and gas, geological exploration, and coal mining industries.

KoneCarbide offers top and consistent quality PDC cutters/inserts which are made from tungsten carbide substrates with a layer of polycrystalline diamond, combining the ultra-high hardness, abrasion resistance, and thermal conductivity of polycrystalline diamond with the compressive strength of tungsten carbide. The specially designed surface patterns on the tungsten carbide blanks are for better combination with PCD. All of our finished PDC inserts will go through our in-house quality inspection before delivery.

KoneCarnide PDC Cutter Features:

- Micro-grain tungsten carbide;

- Super high wear, impact, abrasion, and corrosion resistance;

- Heat-resistance temperature is up to 750° (two minutes);

- Suitable for soft to medium-hard rock formation;

- Premium and consistent quality within a bulk;

- Competitive price;

- Customization service.

Request for quotation for detailed information (MOQ, price, delivery, etc) if you are interested in our PDC cutters for PDC bits. Our sales team and engineers are ready to provide the most cost-efficient solution for you.