Have you ever thought about the process of how damaged and uneven roads are transformed into smooth and newly paved surfaces? The answer lies in the impressive technique of road milling, with the essential component being the road milling teeth. These teeth are small but powerful tools that play a significant role in renovating our roads, guaranteeing safer and more comfortable travels for everyone. Today, we’ll explain everything about road milling teeth, including components, applications, types, and benefits.

Components

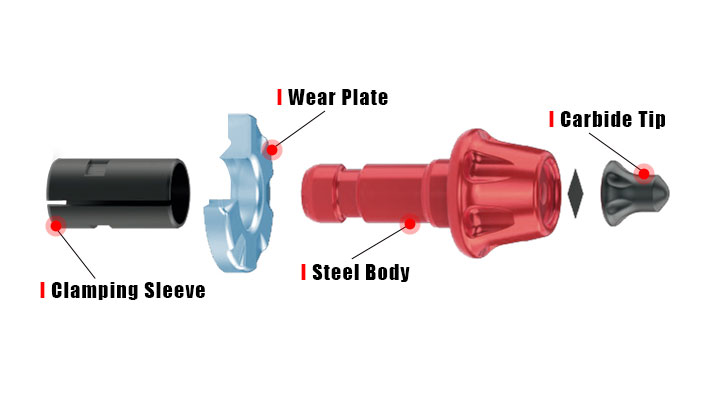

Road milling teeth consist of four parts: a carbide tip, a steel body, a wear plate, and a clamping sleeve.

Carbide tip

As the name suggests, carbide tips of road milling teeth are manufactured from tungsten carbide. They have excellent hardness and wear resistance, improving cutting performance and service life of teeth. These carbide tips are perfect solutions for all types of materials like soft asphalt or concrete.

Steel body

The design of the solid steel body can efficiently remove chips and extend its service life.

Wear plate

Grooves on the wear plate are helpful in the centering and rotation of the pick. Besides, they can reduce the wear of the holder and improve service life.

Clamping sleeve

With a clamping sleeve, the conical pick can be perfectly clamped in the tool holder.

Applications

Road milling teeth are indispensable implements used in a wide variety of activities associated with roadworks, including road construction, surface smoothing, pavement recycling, utility trenching, airport runway upkeep, and parking lot resurfacing. These implements are designed to ensure the accurate and efficient removal of pavement material, thereby ensuring that road surfaces are of the highest quality and are safe for travel.

Types

Different types of road milling teeth are available in the market, and each is designed for specific milling tasks and material types. The commonly used types include carbide-tipped teeth and diamond-tipped teeth. Carbide-tipped teeth are equipped with carbide inserts, which make them durable and ideal for cutting through hard asphalt and concrete surfaces. Diamond-tipped teeth, on the other hand, are known for their superior wear resistance and longevity and are used for cutting through heavily reinforced concrete and tough materials.

Benefits

The utilization of road milling teeth offers numerous advantages in various road construction and maintenance applications. Here are some essential benefits:

- Cost-Effectiveness: Road milling teeth provide cost-effective solutions for road maintenance and construction. Removing only the necessary layers of pavement helps minimize material waste. Additionally, road milling machines equipped with these teeth can recycle the removed pavement material, reducing the need for new materials and lowering project costs.

- Efficient Pavement Removal: Road milling teeth are designed to break and remove pavement material, like asphalt or concrete, efficiently. They can quickly and effectively remove the top layers of the road surface, allowing for efficient pavement removal during road construction or rehabilitation projects. This saves time and labor compared to manual methods of pavement removal.

- Precise Surface Preparation: Road milling teeth enable precise surface preparation for road resurfacing or repair. They can remove specific layers of pavement to achieve the desired depth and smoothness, ensuring proper bonding between the old and new pavement layers. This precision helps to create a level and even road surface, enhancing ride quality and reducing the risk of accidents.

- Increased Productivity: Road milling teeth enhance productivity in road construction and maintenance projects. Compared to manual methods, road milling machines equipped with these teeth can cover larger areas in less time. This increased productivity allows for faster completion of projects, minimizing road closures and disruptions to traffic flow.

- Improved Safety: By removing surface irregularities, road milling teeth contribute to improved road safety. Bumps, ruts, and potholes can pose hazards to drivers, causing discomfort, reduced vehicle control, and potential accidents. Smoothing the road surface with milling teeth helps to eliminate these hazards, providing a safer driving experience.

- Reduced Environmental Impact: Road milling teeth support sustainable road construction practices. Recycling the removed pavement material reduces the demand for new aggregates and minimizes the environmental impact of extracting and producing new materials. Additionally, road milling machines equipped with efficient dust control systems help mitigate airborne dust emissions during the milling process, promoting a healthier working environment.

- Versatility: Road milling teeth come in various designs and sizes, allowing for versatility in different applications. They can be customized to adapt to specific road conditions, such as hard asphalt or concrete surfaces, as well as different pavement thicknesses. This versatility makes road milling machines with interchangeable teeth suitable for a wide range of projects.

If you are in search of high-quality road milling teeth, KoneCarbide offers a premium solution. Our milling teeth are manufactured using superior carbide tips and solid steel bodies, ensuring that they are durable and efficient replacements for leading brands such as Wirtgen and Kennametal. Reach out to us today to discover more about our dependable and trustworthy supply alternatives!