In large construction projects, foundation drilling is an extremely valuable and important process, but it is often underappreciated. Whether in constructing bridges or building skyscrapers, foundation drilling plays a vital role. Many people may wonder what it is and why it is so important. Today, this article will answer these questions one by one. Let’s begin with the definition.

What Is Foundation Drilling?

Foundation drilling is, in short, utilizing large drilling rigs to bore big holes deep in the ground. The purpose is to place structures such as piers, caissons, or bored piles that are used as supports for the foundation deep into the holes.

Foundation drilling is an extremely complicated process that includes various methods and techniques. As mentioned above, the most common application of foundation drilling is to insert structures like piles to maximize the load-bearing capacity of the foundation, especially for new projects. It may sound simple, but it is actually very difficult. The Foundation drilling process requires considerable expertise in drilling as well as efficient coordination. In addition, there are other factors that need to be considered, including weather, soil composition, surroundings, unforeseen circumstances, etc.

Why Is Deep Foundation Needed?

For small structures like houses, a shallow foundation that is on the surface of the ground or just below it works well. However, for larger ones like bridges and tall buildings, a shallow foundation is dangerous. Here comes the foundation drilling. Through this effective way, we can put the “roots” of the foundation deep into the earth to stop the building from sinking or moving. Bedrock is the hardest and most immovable part under the ground, so in most instances, we rest piles or columns of the foundation on top of it to ensure safety and stability.

Foundation Drilling Methods

There are several common foundation drilling methods that are popular today.

Kelly Drilling

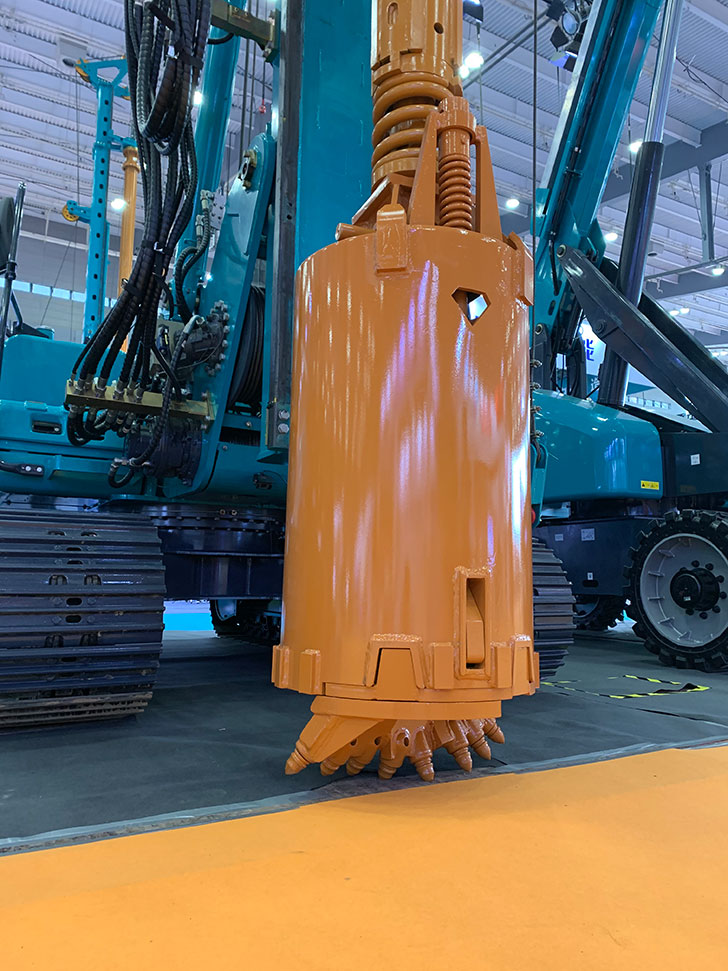

The fundamental purpose of kelly drilling is to drill large-diameter bored piles. Kelly drilling utilizes a drill rod called a “kelly bar” which is famous for its telescopic design. With the telescopic design, a “kelly bar” can go very deep into the ground. This method is suitable for any type of rock and soil, using core barrels, augers, or buckets with replaceable carbide-tipped bullet teeth.

Before the drilling process starts, a temporary protective pile structure is established in advance. The drill rod then extends below the pile and bores into the earth. Next, the rod is withdrawn from the hole and a reinforcement structure is used to strengthen the hole. Now, the temporary protective pile is allowed to be removed and the hole is filled with concrete.

Continuous Flight Augering

Continuous flight augering (CFA), also named auger cast piling, is mainly used to excavate holes for cast-in-place piles and is suitable for wet and granular ground conditions. CFA uses a long auger drill with the function of bringing soil and rock to the surface during the process. Meanwhile, concrete is injected by a shaft under pressure. After the auger drill is removed, reinforcement is inserted into the holes.

Reverse Circulation Air Injection Drilling

When larger boreholes are required, especially holes of up to 3.2-meter diameter, the reverse circulation air injection drilling (RCD) method is used. Generally, RCD applies hydraulic circulation drilling. A liquid current in the annular space between the drill rod and borehole wall is flushed by a pump and flows to the bottom of the hole. During this process, drill cuttings are conveyed to the surface.

Down-the-Hole Drilling

Down-the-hole drilling (DTH) is ideal for projects with the requirement of breaking up hard rocks and boulders. This method utilizes a hammer mounted on a drill bit at the end of the drill rod. Carbide buttons are inserted in the hammer to extend its service life. As the drill bit rotates, compressed air creates high pressure to propel the hammer forward to fracture and impact rocks. Meanwhile, drill cuttings are carried out of the hole to the surface.

Grab Drilling

As one of the oldest dry drilling methods, grab drilling is still widely used nowadays. It is applied when drilling wells with small drilling diameters or creating cast-in-place piles with large diameters. Grab drilling uses a claw with an angled end hanging on a crane to loosen the soil and rocks and then grab them to the surface.