For some countries and regions, a blanket of snow and frigid temperatures show the arrival of winter. Snow removal can be quite challenging for both municipalities and individuals. When it comes to clearing snow and ice effectively, using a proper cutting edge is essential. With so many options available, it is a daunting task to choose the right one. However, today, we will explore the factors to consider and the key benefits of different types of snow plow cutting edges. After reading this article, we believe you will gain the knowledge to choose the ideal cutting edge, guaranteeing efficient snow removal during the winter season.

Types of snow plow cutting edges

First of all, let’s take a look at what choices we have.

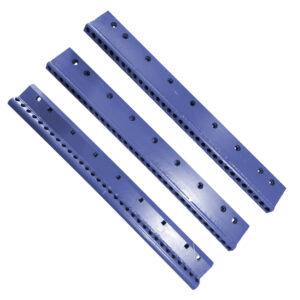

- Carbide cutting edges

Carbide cutting edges are equipped with tungsten carbide inserts on the edge. The body of the carbide cutting edge is usually made from steel. Tungsten carbide is renowned for its exceptional wear resistance and durability. Snow plow cutting edges are ideal for dealing with the most abrasive surfaces. Because of the high hardness of tungsten carbide, this type of cutting edge may damage the road. It is best suited for surfaces that are frequently repaved. Tungsten carbide is more expensive than steel, so carbide cutting edges come with a higher price tag, but they feature exceptional durability. If you’re suffering from the frequent changes in your steel cutting edge, invest in a carbide cutting edge.

- Steel cutting edges

Steel cutting edges are the most commonly used types of snow plow cutting edges. They are famous for their versatility and can withstand twisting, bending, and uneven wear. Unlike carbide cutting edges, steel edges minimize any potential damage to road surfaces. Since they are not as wear-resistant as carbide, steel cutting edges require more frequent replacement, yet with a relatively lower replacement cost.

- Rubber cutting edges

Rubber cutting edges stand out as the most cost-effective material compared to other types of cutting edges. Instead of scraping into road surfaces, a rubber cutting edge glides over the surface due to its elasticity. Then there is an additional salt application to clean the road. Rubber cutting edges are designed to deal with delicate driveways and parking garages. They are less expensive and very soft, minimizing the potential damage to the surfaces.

- Polyurethane cutting edges

Polyurethane cutting edges are less strong than steel but stronger than rubber. As a result, a poly cutting edge is more durable than a rubber cutting edge and can effectively scrape surfaces. Poly cutting edges are designed for decorative roads like shopping malls. Their prices are greatly influenced by their chemical makeup and quality.

How to recognize signs of wear on your cutting edge?

Several factors impact the wear of your cutting edge, such as surface conditions, climate, cutting edge material, contact pressure, and speed. Regular inspection is crucial to extend the service life of your cutting edge. When you notice any signs of uneven wear, cracks, or other forms of damage on your cutting edge, it’s the right time for a replacement. Daily maintenance is so important that you can greatly prolong the longevity of your snow plow cutting edge.

How to choose the right cutting edge?

When selecting an appropriate cutting edge, there are several factors to take into account, including prevailing snow conditions, the nature of the ground surface, and more. In addition, remember to learn about the material grade of cutting edges. As we mentioned above, carbide cutting edges are ideal for plowing abrasive surfaces but will be likely to damage the road. If your job is to remove snow and ice on abrasive roads, choose a carbide cutting edge. But if you are working with decorative surfaces, poly cutting edges are more suitable. Rubber cutting edges are soft, quiet, and won’t damage the road, suitable for parking garages. Steel cutting edges are versatile and can meet most of your requirements.

KoneCarbide is offering premium-quality carbide cutting edges and JOMA 6000. We specialize in the manufacturing and supply of tungsten carbide products and solutions. We only use 100% virgin WC powder, ensuring the performance and durability of our cutting edges. Contact us today for further information such as minimum order quantity (MOQ), price, payment, delivery, and more. Our salespeople are ready to serve you.