When winter comes, roads are covered with snow and ice, so the battle against treacherous driving conditions begins. Municipalities and snow removal professionals rely on snow plows to clear the way, ensuring safe and accessible roads for commuters. However, selecting the right type of cutting edge for snow plows is crucial for efficient and effective snow removal. JOMA 6000 and carbide snow plow cutting edges are two contenders that have gained popularity for their outstanding durability, performance, and ability to withstand demanding winter conditions. Today, let’s compare these two cutting edges: JOMA 6000 vs carbide snow plow cutting edges, exploring their features in detail.

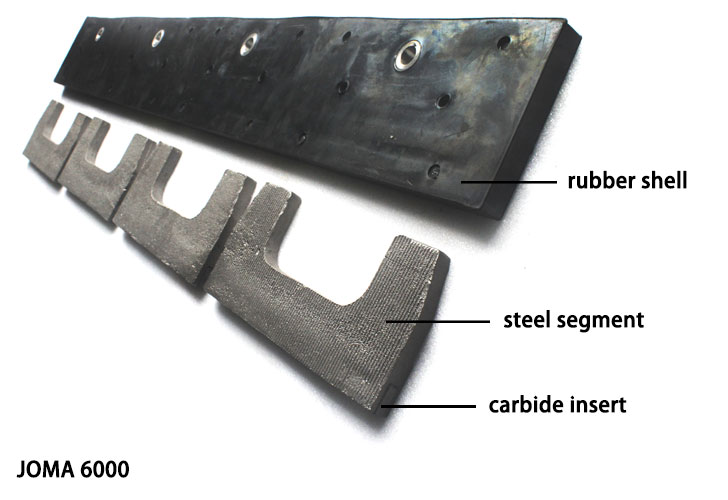

(JOMA 6000 blade↑)

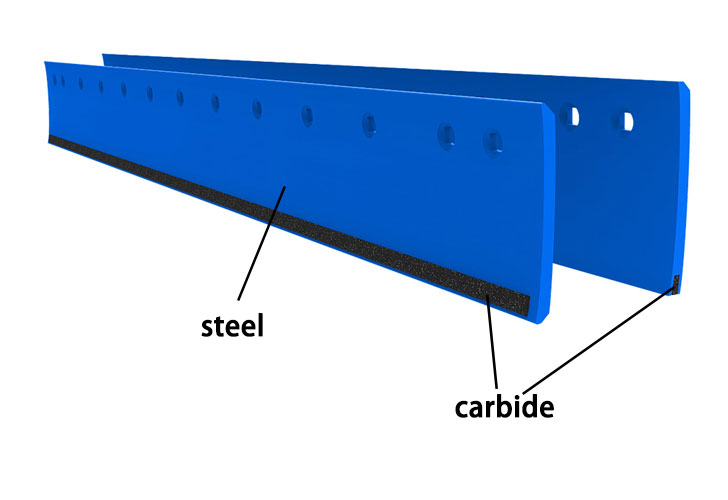

(Carbide snow plow cutting edge↑)

JOMA 6000 vs. Carbide Snow Plow Cutting Edges: Similarities

- Utilizing Carbide Inserts

Both JOMA 6000 and carbide snow plow blades employ tungsten carbide inserts to expand lifespan. Tungsten carbide, or carbide, is one of the hardest materials in the world, featuring outstanding wear resistance. Carbide inserts allow these two types of snow plow cutting edges to work under tough conditions, such as heavily icy highways.

KoneCarbide manufactures and supplies high-grade carbide inserts or bars for snow plow blades. If you’re looking for a reliable supplier, contact us today!

- Excellent Durability

Equipped with hard tungsten carbide inserts, the service life of both JOMA 6000 and carbide snow plow cutting edges are greatly extended. As a result, the snow plow performance is enhanced and there is less downtime.

- Cost-effective

These two types of snow plow blades may have higher initial costs compared to traditional steel edges, their extended lifespan and reduced maintenance requirements make them a cost-effective investment in the long run. Snow removal professionals can benefit from long-term cost savings and increased efficiency with these cutting edges.

JOMA 6000 vs. Carbide Snow Plow Cutting Edges: Differences

- Structure

The JOMA system is a revolutionary innovation in the snow plowing industry. JOMA 6000 blades comprise carbide inserts or bars, steel segments, and a rubber shell. Steel segments contain several tungsten carbide inserts and are encased in the rubber shell. Compared to JOMA 6000 blades, the structure of carbide snow plow blades is more simple. A carbide cutting edge consists of a long carbide insert and a steel blade. The insert is brazed into the edge of the steel blade.

- Vibration and Noise

During operation, the JOMA 6000 blade effectively minimizes vibration and sound thanks to the rubber casing. In contrast, carbide snow plow blades can produce unwanted vibration and noise when removing snow without the aid of the rubber shell.

- Road Protection

Additionally, the sectional design of JOMA 6000 cutting edges enables them to follow the contours of the road, resulting in reduced road damage and efficient snow and ice removal. Conversely, full-length carbide snow plow blades may cause damage to the road during operation.

Apart from snow plow carbide inserts, KoneCarbide also supplies both JOMA 6000 and carbide snow plow cutting edges. Request a quote today! Our salespeople are ready to provide tailor-made solutions for you.