A vertical shaft impact (VSI) crusher, also known as a sand-making machine, can efficiently turn small rocks or other materials into sand. By using a high-speed rotor with several carbide-inserted tips, a VSI crusher can accelerate the rocks and throw them against a crushing chamber’s stationary walls, thus breaking the rocks. It is widely used in the construction, mining, quarrying, and recycling industries. In this article, we will explore what a VSI crusher is and its components. Scroll down to discover the details.

What is a VSI crusher?

A vertical shaft impact (VSI) crusher is a crucial tool for various crushing applications. Its primary purpose is to produce products used in the construction industry, such as aggregates. Besides, in the field of recycling building materials such as asphalt and concrete, VSIs are also of vital importance. In addition, another key application of VSI crushers is producing industrial sand, which is a component in the manufacturing of products like ceramics.

Unlike a jaw crusher or a cone crusher, a VSI crusher is capable of producing well-shaped and evenly graded aggregates, making it suitable for applications where consistent aggregates are needed, such as concrete production.

How does a VSI crusher work?

The crushing process starts when the raw material enters the crusher through a feed hopper and proceeds to the rotor via a central entrance. Then, a spinning pump propels the raw material, utilizing the VSI’s vertical axis rotation. Upon entering the crusher, the aggregate feed encounters several rotor tips and other aggregate pieces. As the name suggests, the material is crushed through the high-speed impact inside the VSI crusher.

VSI rotors

As we mentioned above, a VSI crusher employs a rotor to finish the crushing work. A VSI rotor plays a vital role in the crushing process. It mainly comprises a rotor body and several wear-resistant rotor tips. These rotor tips contain tungsten carbide inserts, greatly enhancing the durability and performance of VSI rotors.

KoneCarbide has rich experience in supplying VSI rotors and rotor tips, including Metso and Sandvik. If you are looking for a reliable supplier, contact us today!

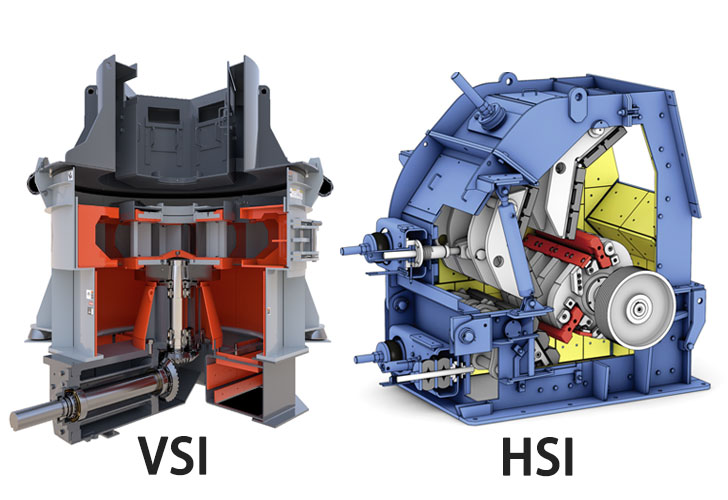

VSI crushers vs. HSI crushers

VSI crushers and HSI (Horizontal Shaft Impact) crushers are both widely used in crushing applications. What are the differences between them? What are the factors to consider when selecting the right crusher?

(Image source: power-equip.com; bhs-sonthofen.com)

Cost

Generally speaking, an HSI crusher is less expensive than a VSI crusher, but it offers a lower throughput rate. If you require a high production rate, a VSI crusher is more suitable.

Crushing material

HSI crushers are perfect for softer materials, while VSI crushers are ideal for harder materials.

Crushing stage

Usually, there are three crushing stages: primary, secondary, and tertiary crushing. A jaw crusher is used in the primary crushing stage to reduce large rocks or stones to a manageable size for further processing. In the secondary crushing stage, cone crushers and HSI crushers are employed to further break the material down into smaller fragments. Tertiary crushing aims to produce the final required particle size and shape for specific purposes, such as industrial sand. VSI crushers are used in this stage.